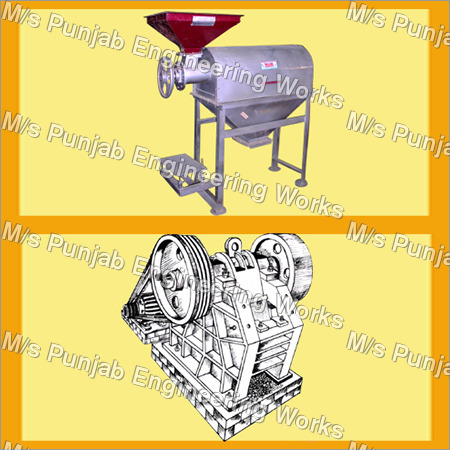

Rotor Siever

Rotor Siever Specification

- Feeding System

- Manual or Conveyor

- Phase

- Single Phase

- Power Source

- Electric

- Automation Grade

- Automatic

- Speed Mode

- Fixed

- Machine Type

- Rotary Sieve

- Operating Temperature

- Normal ambient

- Features

- Dust Free Operation, Precise Output

- Noise Level

- Low Noise

- Frequency

- 50 Hz

- Function Type

- Screening

- Product Type

- Rotor Siever

- General Use

- Industrial Screening

- Material

- Stainless Steel

- Type

- Screening Machine

- Weight (kg)

- 300 kg approx.

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Control

- Installation Type

- Free Stand

- Power

- 1.5 HP

- Dimension (L*W*H)

- 2000 x 900 x 1700 mm

- Raw Material

- Stainless Steel, Mild Steel

- Feature

- High Screening Efficiency

- Color

- Silver

About Rotor Siever

Banking on our 5 decades of industrial experiences, we have been manufacturing and supplying an innovative range of Rotor Siever/Jaw Crusher. These machines are used in various industries including coal, metal processing and metallurgical for sieving and crushing of metals. Precisely designed at our state of the art machining facility, our Rotor Siever/Jaw Crusher is made using quality stainless steel procured from authentic vendors of the market. We can also customize these machines as per the needs of the clients.

Features:

- Sturdy design

- Rust proof finish

- Easy installation

Further Details:

- Power consumption 1hp to 3hp

- Capacity 150kg to 600kg per hour

- Power Consumption : 3hp to 60hp

- Capacity 1500 to 8200 Kg per hour

Efficient Industrial Screening

The Rotor Siever excels in separating and mixing materials in industrial environments. Its automatic operation and PLC control system ensure thorough and accurate screening, minimizing manual intervention. Crafted with high-quality stainless steel, this machine delivers long-lasting, corrosion-resistant performance. Ideal for factories, plants, or any facility needing bulk screening, its low-noise operation and dust-free performance contribute to a healthier workspace.

User-Friendly and Versatile Design

With free-standing installation and fixed speed mode, the Rotor Siever provides flexibility for various screen or mixing requirements. Its rectangular form and moderate size allow easy placement in production lines. Suitable for use as a distributor, exporter, manufacturer, supplier, or trader in India, the machine supports manual or conveyor feeding systems, optimizing workflow. Whether you require precise sifting or consistent mixing, it maintains a reliable output.

FAQs of Rotor Siever:

Q: How is the Rotor Siever operated and controlled?

A: The Rotor Siever operates automatically and is managed through a PLC control system, providing streamlined process control without the need for computerization. This ensures consistent performance and reliability during industrial screening tasks.Q: What types of raw materials can be processed with this machine?

A: The machine is built to handle a range of raw materials, including stainless steel and mild steel. Its high screening efficiency and sturdy construction allow it to process various industrial powders, granules, or mixtures effectively.Q: When is it suitable to use the Rotor Siever in production environments?

A: The Rotor Siever is ideal for use when precise screening and mixing are required, especially in ambient temperature conditions. Its automatic and dust-free operation makes it particularly suitable for continuous or batch processing in industrial settings.Q: Where can the Rotor Siever be installed?

A: Installation is straightforward thanks to its free-standing design. It can be placed in factories, manufacturing plants, and warehouses, making it convenient for distributors, exporters, suppliers, or traders operating in India.Q: What is the process of feeding materials into the Rotor Siever?

A: Materials can be fed manually or via a conveyor system, offering flexibility to match different operational needs. Once inside, the automatic rotary mechanism screens and mixes the material with high precision.Q: How does using this machine benefit my industrial operations?

A: Utilizing the Rotor Siever enhances productivity with its high screening efficiency, low noise, and dust-free operation. Accurate separation and mixing reduce waste and improve the quality of final products, streamlining workflow across your facility.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Food Processing Machinery Category

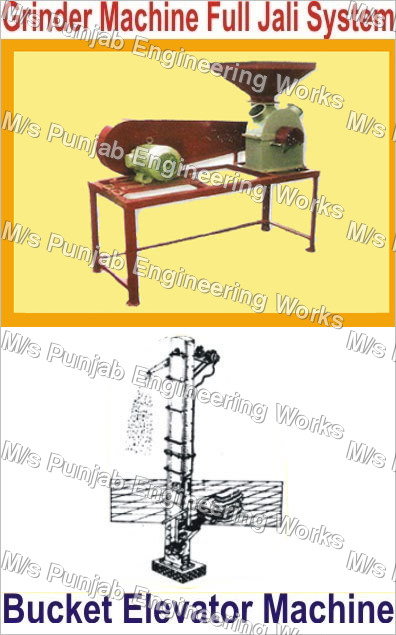

Spices Grinder Machine

Price Range 69000.00 - 106000.00 INR

Minimum Order Quantity : 1 Piece

Material : Other, Mild Steel

Installation Type : Other, Floor Mounted

Power Source : Electric

Computerized : No

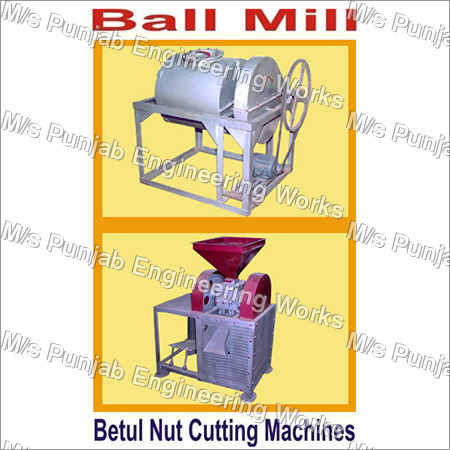

Betel Nut Cutting Machine

Material : Stainless Steel

Installation Type : Free Stand

Power Source : Electrical

Computerized : No

Besan Plant Impact Pulverizer

Price Range 195000.00 - 250000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS