Zinc Ash Crushing Grinding Machine

MOQ : 1 Piece

Zinc Ash Crushing Grinding Machine Specification

- Shape

- Rectangular

- Phase

- Three Phase

- Torque

- High Torque Motor Driven

- Diameter

- 400 mm (Rotor)

- Product Type

- Crushing Grinding Machine

- General Use

- Industrial Processing of Zinc Ash

- Material

- Mild Steel

- Type

- Crusher & Grinder

- Weight (kg)

- 1200 kg

- Computerized

- No

- Automatic

- Yes

- Touch Screen

- No

- Surface Treatment

- Paint Coated

- QC System

- Standard Quality Control

- Tolerance

- 0.02 mm

- Drawing

- Available on Request

- Voltage

- 380 V

- Dimension (L*W*H)

- 2500 mm x 1200 mm x 1500 mm

- Color

- Blue/Grey

Zinc Ash Crushing Grinding Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Months

About Zinc Ash Crushing Grinding Machine

Roller Mill

Power Consumption : 5hp to 50hp

Capacity 100Kg to 5000 Kg per hour.

Note : These machines have low maintenance cost other than pulverizers

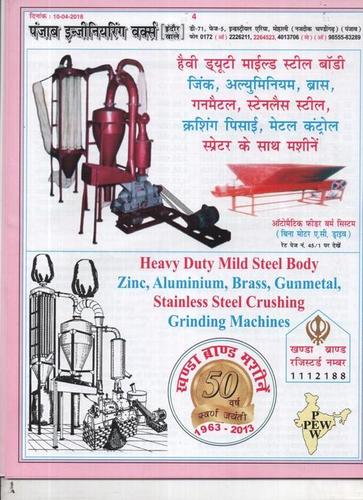

Zinc Ash / Brass Crushing Machine

Power Consumption : 5hp to 50hp

Capacity 100Kg to 5000 Kg per hour.

Note : These machines have low maintenance cost other than pulverizers

Exceptional Crushing and Grinding Performance

Engineered with a high torque motor and a large 400 mm rotor diameter, this machine ensures effective crushing and grinding of zinc ash. The automatic operation minimizes manual intervention, increasing throughput while maintaining a consistent material size, all within tight tolerance specifications. Its sturdy design and paint-coated body provide long-lasting service in demanding industrial environments.

Precise Tolerance and Reliable Quality Control

With a guaranteed tolerance of 0.02 mm and standard quality control systems in place, the Zinc Ash Crushing Grinding Machine delivers reliable and uniform results. Manufacturers can depend on consistent output, which improves downstream processing efficiency and reduces material wastean essential advantage for industrial operations seeking quality assurance.

FAQs of Zinc Ash Crushing Grinding Machine:

Q: How does the Zinc Ash Crushing Grinding Machine benefit industrial processing?

A: This machine streamlines zinc ash handling by automating the crushing and grinding process, reducing manual labor and increasing processing capacity in industrial settings. Its precise tolerance minimizes material loss, resulting in better recovery rates and improved production efficiency.Q: What materials and treatments ensure the durability of the machine?

A: The machine is built from mild steel and features a paint-coated finish, which provides resistance against corrosion and wear, making it suitable for continuous operation in challenging industrial environments.Q: Where can this Zinc Ash Crusher & Grinder be used effectively?

A: The machine is designed for use in zinc processing plants, recycling facilities, and any industrial setup where zinc ash needs to be crushed and ground efficiently. It can be deployed by manufacturers, exporters, distributors, and traders throughout India.Q: What is the process for obtaining machine drawings?

A: Detailed machine drawings are available on request. Interested customers should contact the manufacturer or supplier directly to receive these technical documents for installation or integration planning.Q: When is regular quality control conducted on the machine?

A: Standard quality control checks are performed throughout the manufacturing process and prior to shipment. This ensures the machine conforms to industry standards for performance, safety, and reliability.Q: How is the machine operated, and does it require special training?

A: As a fully automatic machine, it requires minimal manual intervention during operation. Basic operational training is recommended to ensure safety and optimal use, but advanced computer skills or touch screen proficiency are not required.Q: What are the main advantages of using a high torque motor in this machine?

A: The high torque motor allows the machine to handle large volumes of zinc ash with ease, resulting in efficient crushing and grinding. This motor also contributes to consistent speed and power delivery, reducing downtime and increasing productivity.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Zinc Ash Crushing grinding machine Category

Zinc Ash Crushing Pulveriser Machine

Control System : Manual, Other

Weight (kg) : Heavy Duty Exact weight varies

Dimension (L*W*H) : Customizable

Automatic : No

Shape : Vertical Machine Design

Touch Screen : No

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS