Spices Grinder Machine

MOQ : 1 Piece

Spices Grinder Machine Specification

- Power Source

- Electric

- Frequency

- 50 Hz

- Speed Mode

- Variable

- Heating Method

- Air Cooled

- Function Type

- Grinding

- Feeding System

- Manual

- Machine Type

- Spices Grinder

- Noise Level

- <70 dB

- Operating Temperature

- Ambient

- Features

- Optimal Grinding, Durable Structure

- Phase

- Single Phase

- Product Type

- Spices Grinder Machine

- General Use

- Grinding of Spices

- Material

- Mild Steel

- Type

- Grinding Machine

- Weight (kg)

- 125 kg

- Product Shape

- Rectangular

- Computerized

- No

- Automatic

- Semi Automatic

- Control System

- Push Button

- Installation Type

- Floor Mounted

- Power

- 3 HP

- Dimension (L*W*H)

- 1100 x 450 x 1200 mm

- Raw Material

- Mild Steel

- Feature

- Low Noise, High Efficiency

- Color

- Grey

Spices Grinder Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Months

About Spices Grinder Machine

Grinder Manufacturer:-

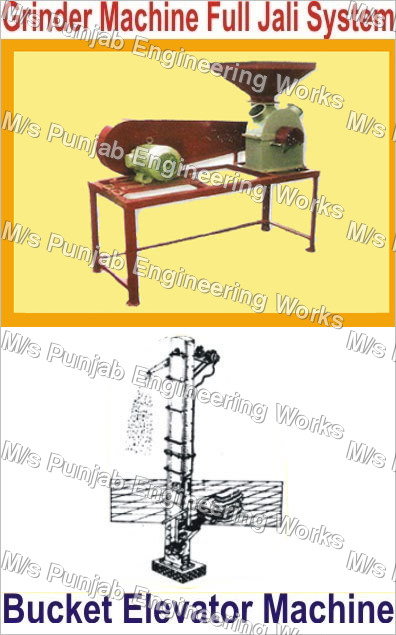

Spices Grinding Mill

Used in spices, medicines, pharmacy, besan, bakeries to grind raw material in various mesh. Power consumption : 1hp to 100hp Capacity : 40kg to 3500kg per hour Other capacities and in stainless steel body can be made on demand. |

Exceptional Grinding Efficiency

Harness the high-efficiency power of our spices grinder machine, driven by a 3 HP copper wound induction motor. Capable of handling an input feed size up to 15 mm and a hopper capacity of 10 kg, this machine ensures rapid, consistent grinding, making it ideal for industrial-scale spice processing.

Durable and User-Friendly Design

Constructed from powder-coated mild steel for resilience, this grinder is built to last and withstand continuous commercial use. Heavy-duty castor wheels and a rectangular form enhance maneuverability, while easy removable parts simplify cleaning and maintenance requirements remain low.

Advanced Safety and Convenience

Safety is prioritized through an integrated safety interlock and a self-lubricating system, reducing operational risks and maintenance frequency. The push-button control system and noise reduction technology (<70 dB) create a comfortable and secure working environment for operators.

FAQs of Spices Grinder Machine:

Q: How does the safety interlock feature enhance operation safety in the spices grinder machine?

A: The safety interlock ensures that the machine cannot operate unless all components are securely fitted, thereby minimizing accidental startups and protecting users during maintenance or cleaning.Q: What process should be followed for cleaning the spices grinder?

A: The machine is designed with easy removable parts, allowing users to quickly disassemble, clean, and reassemble it. Disconnect the power, remove the hopper and blade assembly, wash the parts with water or a mild detergent, and allow them to dry before reassembling.Q: What benefits does the copper wound induction motor provide for commercial grinding?

A: The copper wound induction motor delivers higher efficiency, reliable power output, and enhanced durability, ensuring consistent operation over prolonged periods common in commercial or industrial settings.Q: Where is this grinder best used, and what types of businesses benefit most?

A: This grinder is ideal for commercial kitchens, food manufacturing units, spice processing industries, and industrial kitchens in India. Distributors, exporters, manufacturers, suppliers, and traders can all benefit from its versatile commercial and industrial applications.Q: What is the expected lifespan and maintenance requirement of this grinder?

A: With robust construction and a self-lubricating system, the machine offers a lifespan of up to 10 years and requires minimal routine maintenance, making it cost-effective over the long term.Q: How does the noise reduction technology contribute to a better working environment?

A: Integrated noise reduction technology maintains the machines noise levels below 70 dB, promoting a quieter workspace and reducing hearing strain for operators.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Food Processing Machinery Category

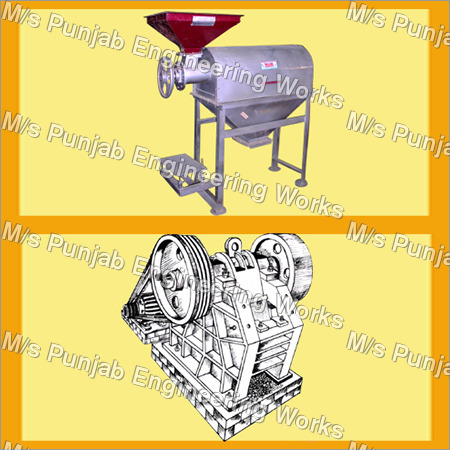

Rotor Siever

Product Type : Rotor Siever

Automatic : Yes

Material : Stainless Steel

Feature : Other, High Screening Efficiency

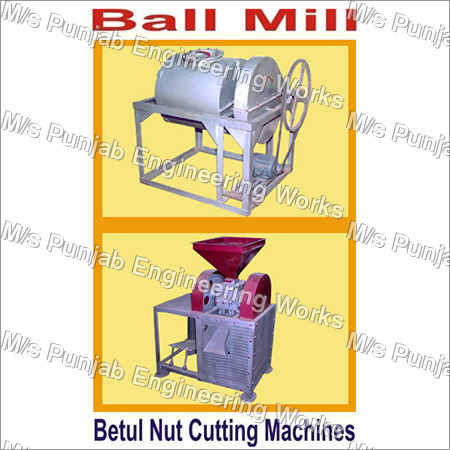

Betel Nut Cutting Machine

Product Type : betel nut cutting machine

Automatic : Yes

Material : Stainless Steel

Feature : High Efficiency

Grinder Machine

Minimum Order Quantity : 1 Unit

Product Type : Grinder Machine

Automatic : Yes

Material : Carbon Steel

Feature : Lower Energy Consumption, Simple Control, High Performance, High Efficiency, Stable Operation

Centrifugal Siever Reel Chhalna Machine

Price Range 171000.00 - 800000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Centrifugal Siever

Automatic : Yes

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS