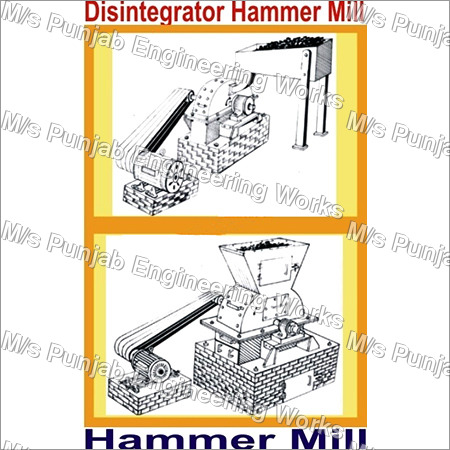

Disintegrator Hammer Mill

MOQ : 1 Piece

Disintegrator Hammer Mill Specification

- Rotation

- Clockwise / Counter Clockwise (customizable)

- Model

- Available in multiple models

- Product Type

- Disintegrator Hammer Mill

- General Use

- Grinding and pulverizing a variety of materials such as grain, spices, minerals, etc.

- Material

- Mild Steel / Cast Iron

- Type

- Hammer Mill

- Capacity

- 100 kg/hr to 2000 kg/hr (model dependent)

- Weight (kg)

- 300 kg to 2500 kg (approx. as per size/model)

- Computerized

- No

- CNC Or Not

- No

- Control System

- Manual

- Floor Space

- Customized as per model

- Fuel Tank Capacity

- Not Required

- WorkingSpeed

- Variable as per material and model

- Spindle Speed

- 2800 RPM (approx.)

- Power

- 5 HP to 30 HP (depending on model)

- Dimension (L*W*H)

- Customized as per model

- Color

- Green / Blue / Custom

Disintegrator Hammer Mill Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1 Piece Per Month

- Delivery Time

- 1 Months

About Disintegrator Hammer Mill

We are committed to manufacture and supply our clients a technically advanced range of Disintegrator Hammer Mill. These machine are for grinding coal, stones, herbs and chemicals in various industries including railway, pharmaceutical, metal processing and metallurgical. In order to manufacture high quality Disintegrator Hammer Mill, our professionals employ advanced machines and utilize quality tested stainless steel procured from the authentic vendors. Our clients have the advantage to customize these mills as per their needs.

Features:

- Sturdy construction

- Easy to in stallion

- Reliable performance

Further Details:

- Power Consumption : 5hp to 40hp

- Capacity 250 to 3000 Kg per hour.

- Power Consumption : 5hp to 40hp

- Capacity 250 to 3000 Kg per hour.

Reliable Grinding Efficiency

Engineered for consistent results, the Disintegrator Hammer Mill delivers efficient milling of grains, spices, and minerals. Its variable speed and multiple model options ensure optimal performance for diverse processing needs, making it a trusted solution for quality output.

Customized Design for Versatility

Each model of the hammer mill is carefully tailored, from dimensions to rotation direction and color, ensuring seamless integration into different workspaces. This adaptability allows industries to select configurations that precisely match their production requirements.

FAQs of Disintegrator Hammer Mill:

Q: How does the Disintegrator Hammer Mill operate without a computerized or CNC system?

A: The hammer mill functions manually, using its control system to adjust settings such as working speed and rotation direction. Operators can manage the process directly, making it reliable and simple to use even in environments without advanced automation.Q: What materials can be processed in the Disintegrator Hammer Mill?

A: The machine is designed to grind and pulverize a broad spectrum of materials, including grains, spices, minerals, and more, making it ideal for various industrial and commercial applications.Q: When should I consider using a variable working speed?

A: Variable working speed is beneficial when handling different materials or working with various models. Adjusting the speed helps optimize the grinding process, ensuring consistent particle size and maximizing efficiency depending on the materials hardness and moisture content.Q: Where can the Disintegrator Hammer Mill be installed in a workspace?

A: Installation is flexible since the floor space and overall dimensions are customizable according to the specific model. This allows seamless placement in diverse industrial settings, ensuring it fits within the available workspace.Q: What is the process for switching rotation direction in this hammer mill?

A: The rotation direction, either clockwise or counter clockwise, can be customized at the time of order. Some models may allow manual adjustment, depending on the users requirements and operational preferences.Q: How does the hammer mill benefit manufacturers and suppliers?

A: Manufacturers and suppliers gain from its high capacity range (from 100 kg/hr to 2000 kg/hr) and durable construction, which provide increased productivity, reduced downtime, and consistent processing results. Its customizable aspects also help adapt to specific production demands.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS